I sincerely apologize for the oversight. Here is the professional English product description for the Automatic Press Cap Machine as requested:

PressSeal PS-5000 Series

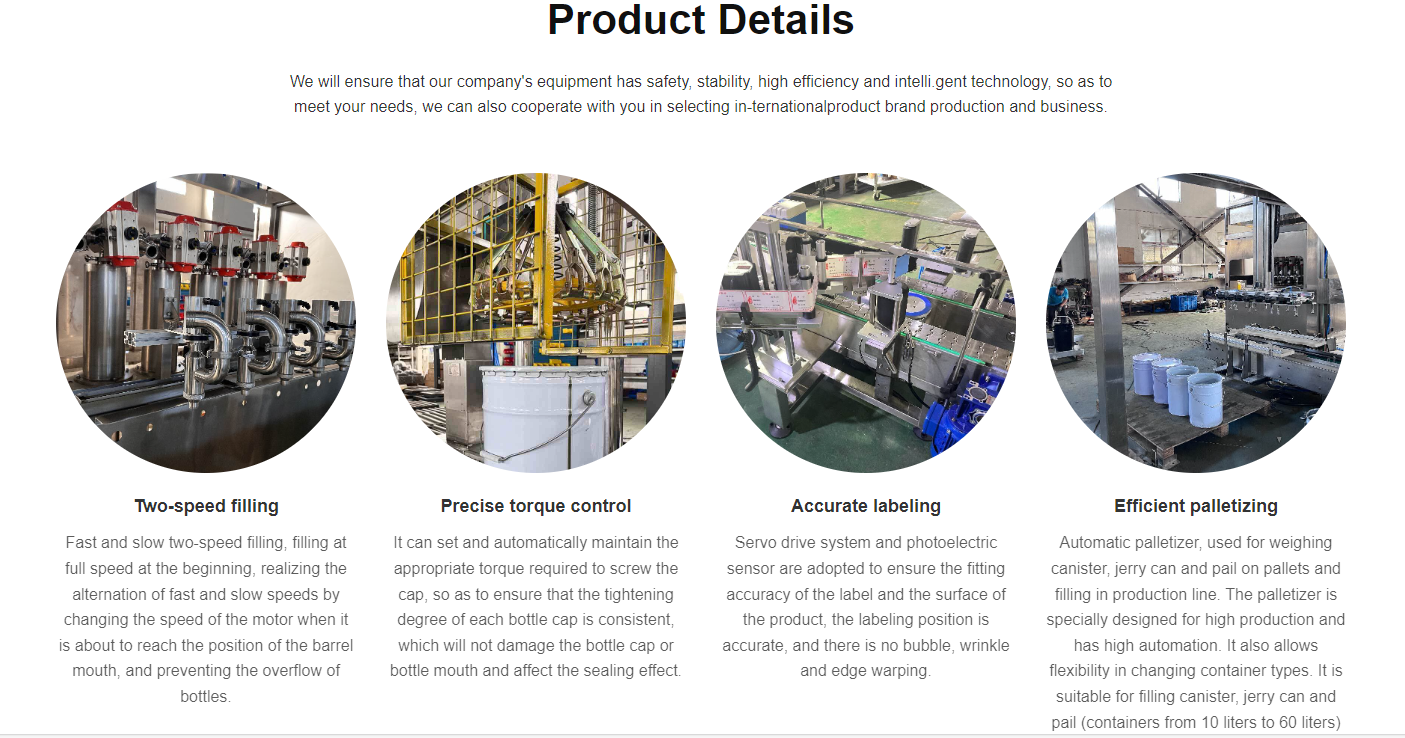

Fully Automatic Press-Type Capping System

450 Caps/Min ? ±0.5% Sealing Force Accuracy ? 10-120mm Cap Range ? Zero-Defect Vision ? Food/Pharma/Chemical Tri-Certified

Technical Specifications

| Parameter | PS-5100 (Standard) | PS-5200A (Aseptic) | PS-5300X (ATEX) |

|---|

| Capacity | 450 Caps/Min | 400 Caps/Min | 380 Caps/Min |

| Sealing Force Accuracy | ±0.5% (50-500N) | ±0.4% (30-400N) | ±0.6% (100-800N) |

| Cap Compatibility | Aluminum-Plastic ? Pull-Tab ? Tamper-Evident ? Child-Resistant | Same + Pharma Aluminum Caps | Same + Metal Drum Lids |

| Cap Diameter Range | 10-120mm | 8-100mm | 15-150mm |

| Capping Technology | Servo Cylinder Direct Press | Maglev Linear Motor | Hydraulic Boost System |

| Positioning Accuracy | ±0.05mm (Vision-Guided) | ±0.03mm (Laser Tracking) | ±0.1mm (Mechanical Guide) |

| Material Contact | 316L SS (Ra<0.8μm) | 316L EP (Ra<0.4μm) | Hastelloy C276 |

| Changeover Time | <15s (Magnetic Quick-Change) | <12s | <18s |

| Vision Inspection | AI Deep Learning System | 5K High-Speed Camera + UV Fluorescence | IR Thermal Defect Detection |

| Defect Detection Rate | 99.998% (0.1mm Flaws) | 99.999% | 99.995% |

| Cleanliness Class | ISO Class 7 | ISO Class 5 | IP66 Rating |

| Power | 380V/50Hz, 5.8kW | 380V/50Hz, 5.2kW | 24VDC Ex ia |

| Certifications | CE, ISO 9001 | FDA 21 CFR 211 | ATEX Zone 1 |

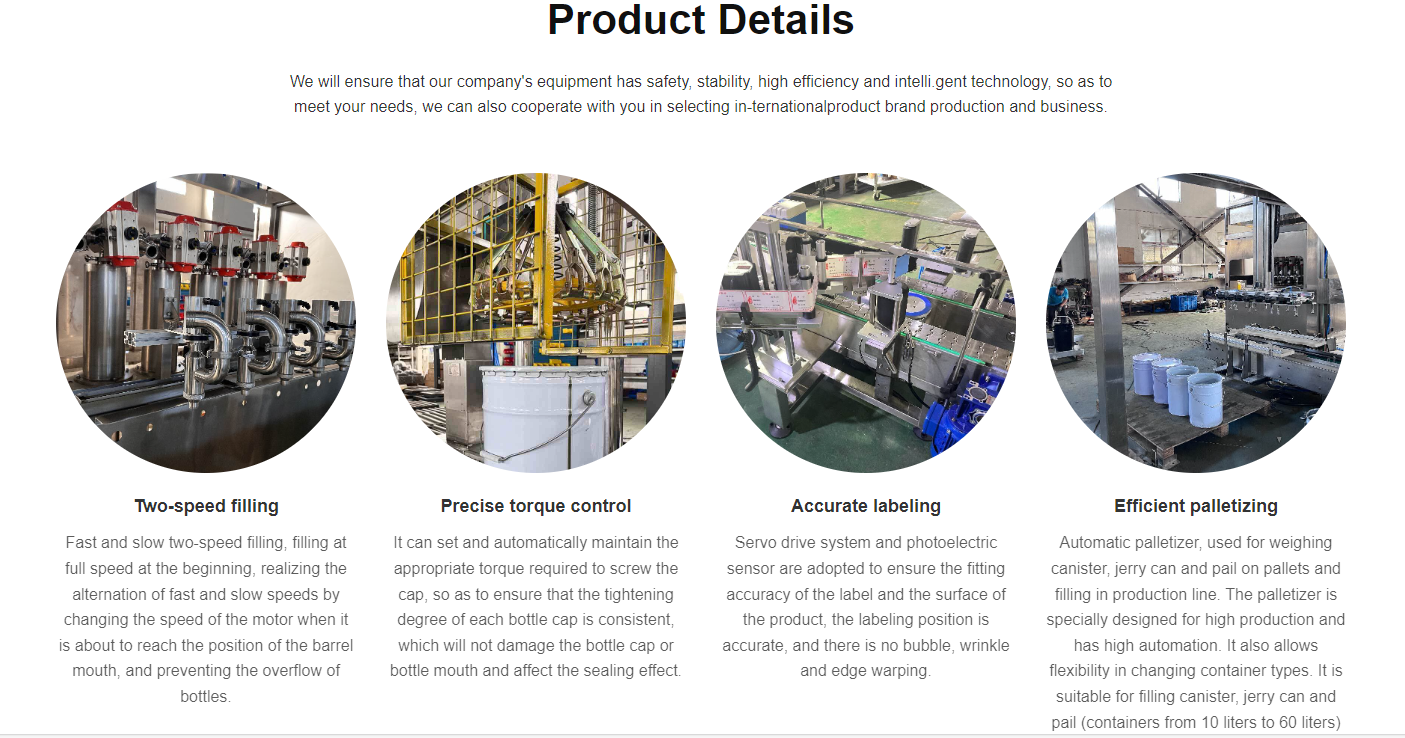

Core Technologies

1. DynaPress? Force Compensation

Performance Comparison:

| Cap Type | Conventional Variance | PS-5000 Precision |

|---|

| 30mm Yogurt Cap | ±15% | ±0.4% |

| 58mm Beverage Cap | ±12% | ±0.5% |

| 110mm Chemical Drum Lid | ±20% | ±0.6% |

2. PureSeal? Aseptic Press

| Technology | Function | Sterility Assurance |

|---|

| Laminar Air Curtain | ISO Class 5 Environment Maintenance | <1 CFU/hour |

| VHP Instant Sterilization | Vaporized H?O? On-Demand | 6-log Microorganism Kill |

| Oil-Free Mechanism | Ceramic Rails + Maglev Drive | Zero Lubricant Contamination Risk |

Industry-Specific Engineering

Dairy & Beverage

| Challenge | Innovation | Certification |

|---|

| Micro-Leakage | Online Helium Mass Spectrometry (10?? mbar·L/s) | ISO 22000 |

| Oxygen Ingress | Laser Welding + N? Blanketing (O?<0.3%) | SQF Level 3 |

| Cap Waste | AI Predictive Force Compensation | Cap Loss Rate <0.01% |

Pharmaceuticals

cGMP Compliance:

Data Integrity:

| System | Compliance |

|---|

| Blockchain Traceability | Per-Cap Pressure Curve Archiving |

| Electronic Batch Record | 21 CFR Part 11 Validated |

Chemicals

| Safety Feature | ATEX Solution | Performance |

|---|

| Intrinsic Safety | Piezoceramic Press Head | Zero Spark Generation |

| Static Dissipation | Surface Resistivity <10? Ω | <0.1kV Charge Accumulation |

| Explosion Venting | 0.5MPa Blast-Resistant Cabin | 90% Shock Absorption |

Smart Control System

**10" AI Touchscreen + PressOS?**

AI Features:

Defect Interception:

| Defect Type | Interception Rate | Response Time |

|---|

| Cap Deformation | 99.99% | 0.05s |

| Bottle Neck Crack | 99.97% | 0.03s |

Predictive Maintenance:

| Component | Alert Threshold |

|---|

| Servo Cylinder Life | 5 Million Press Cycles |

| Rail Wear | Vibration >4.5mm/s RMS |

Technical Advantages

Sealing Technology Revolution

? Speed & Precision Unified:

- 450 Caps/Min (0.13s/Cap)

- ±0.05mm Positioning Accuracy (Mirror-Finish Rails)

- 99.998% Online Yield Rate

? Tri-Industry Certified:

| **Certification** | **Industry**|

|-------------------------|---------------------|

| FDA 21 CFR 211 | Pharmaceuticals |

| EHEDG EL Class I | Food|

| ATEX Zone 1| Chemicals |

? Zero-Contamination Guarantee:

1. Oil-Free Maglev Drive

2. VHP On-Demand Sterilization

3. Laminar Air Shower

Customer Validation

Mengniu Dairy Hohhot Plant:

“After implementing PS-5200A for ambient yogurt line:

Output: 18,000 → 27,000 Bottles/Hour (+50%)

Leakage Rate: 0.8% → 0.002%

Annual Savings: $580,000 (Packaging + Rework)

ROI Period: 6.2 Months”

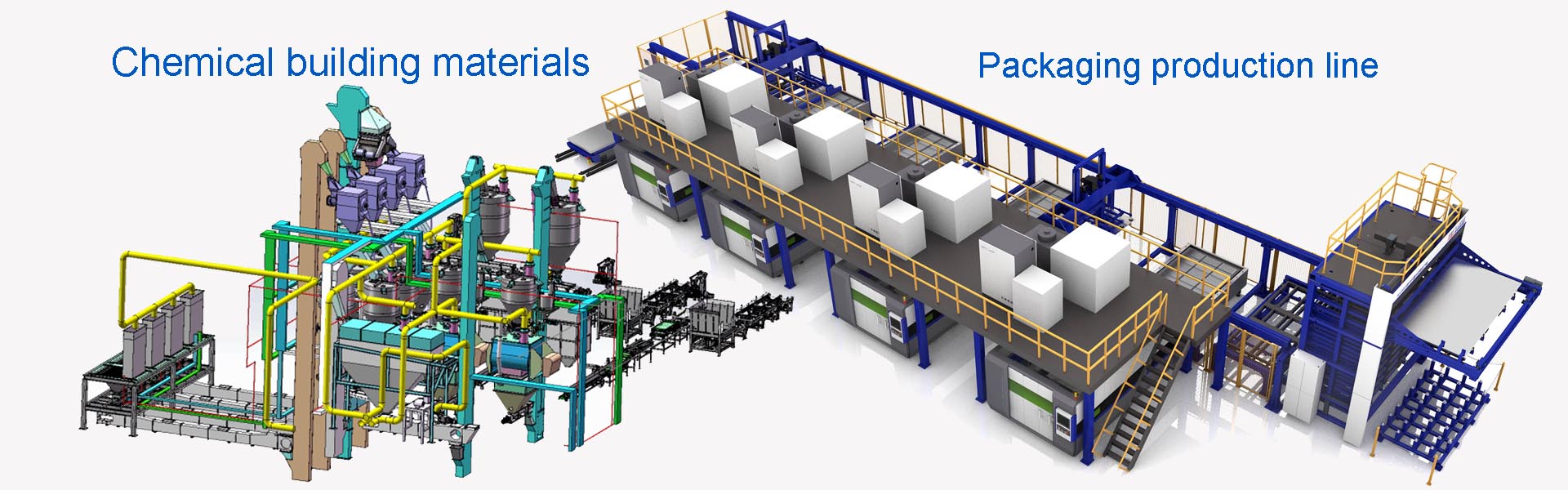

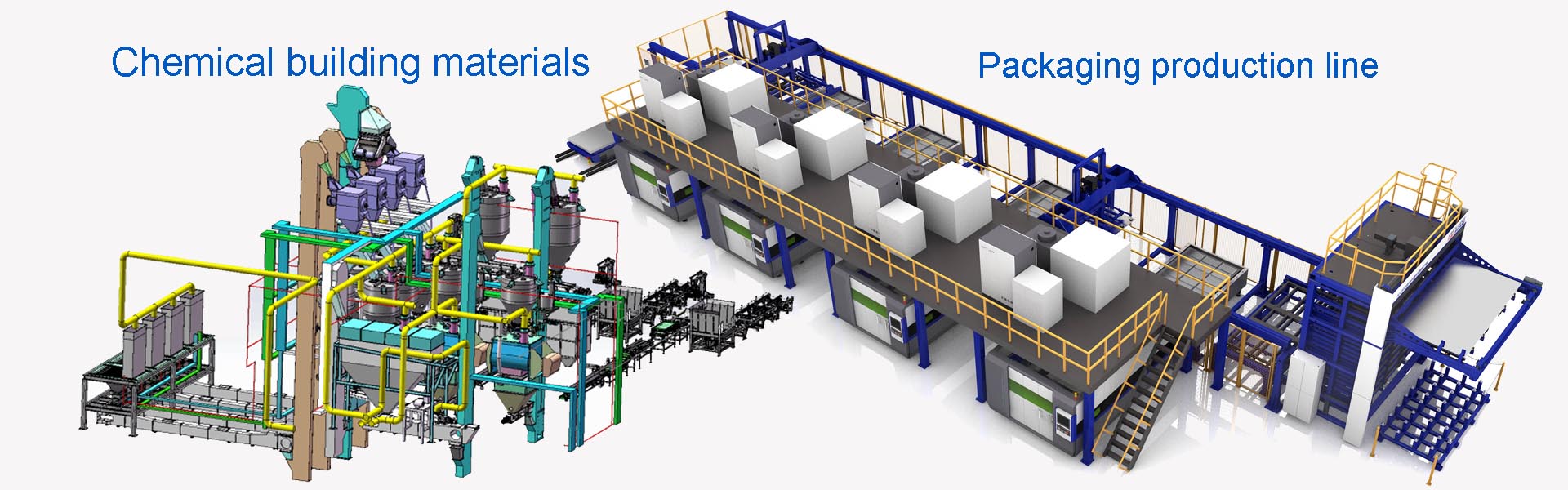

APPLICABLE BARREL TYPE

COMPANY PROFILE

Shanghai Guangzhi Automation Equipment Co., Ltd. is a production and trading company specializing in the weighing industry. We are located in Shanghai, China's economic city, with convenient transportation and export ports all over the world. We cooperate with state-owned factories and international companies, and the quality is guaranteed.

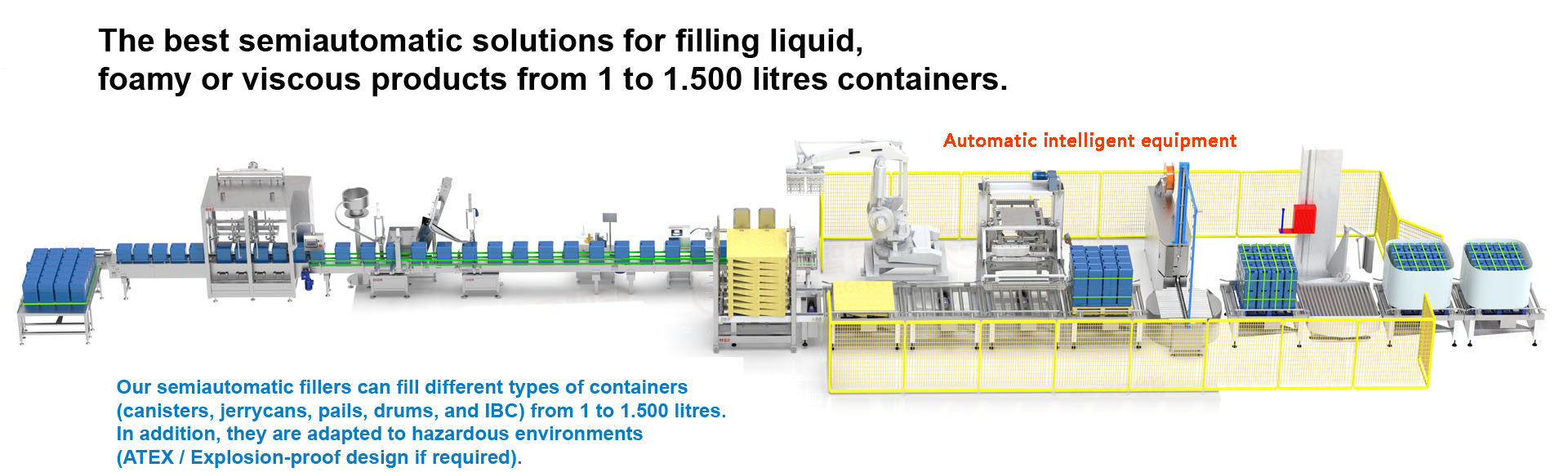

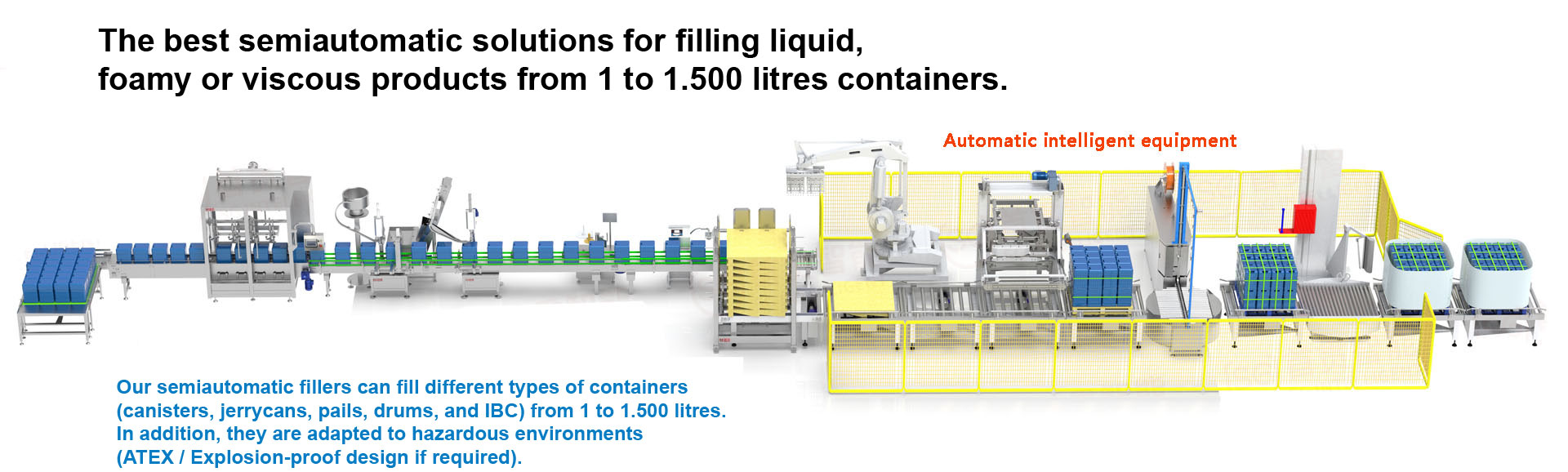

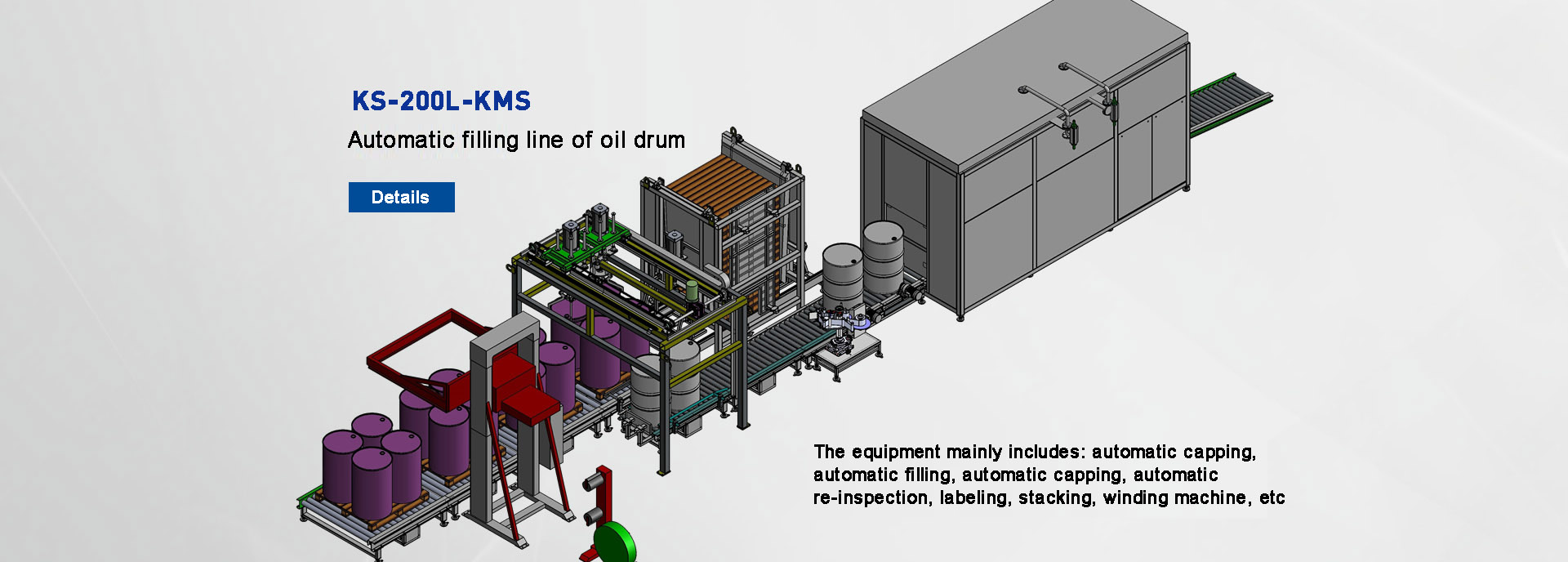

We mainly focus on providing customers with weighing solutions, from commercial scales to industrial weighing machines. Such as pneumatic valve bag packaging machine, dry mix mortar bag packaging machine, cement packaging machine, natural stone powder packaging machine, flour powder packaging machine, wheat packaging machine, potato starch packaging machine, air packaging machine, granule bag packaging machine, grain packaging machine, fertilizer bag packaging machine, lubricant filling machine, 200 kg drum filling machine, 216L drum filling machine, 208L drum filling machine, ton barrel filling machine, IBC barrel filling machine, jumbo bag packaging machine, ton bag packaging machine, 30L pail filling machine, 50L pail asphalt filling machine, ATEX barrel filling machine, explosion-proof filling machine, etc.