Fully Auto White Latex Can Weight Filling Machine

Basic Info.

Product Description

| Model | GZM-30AUTO-2PT |

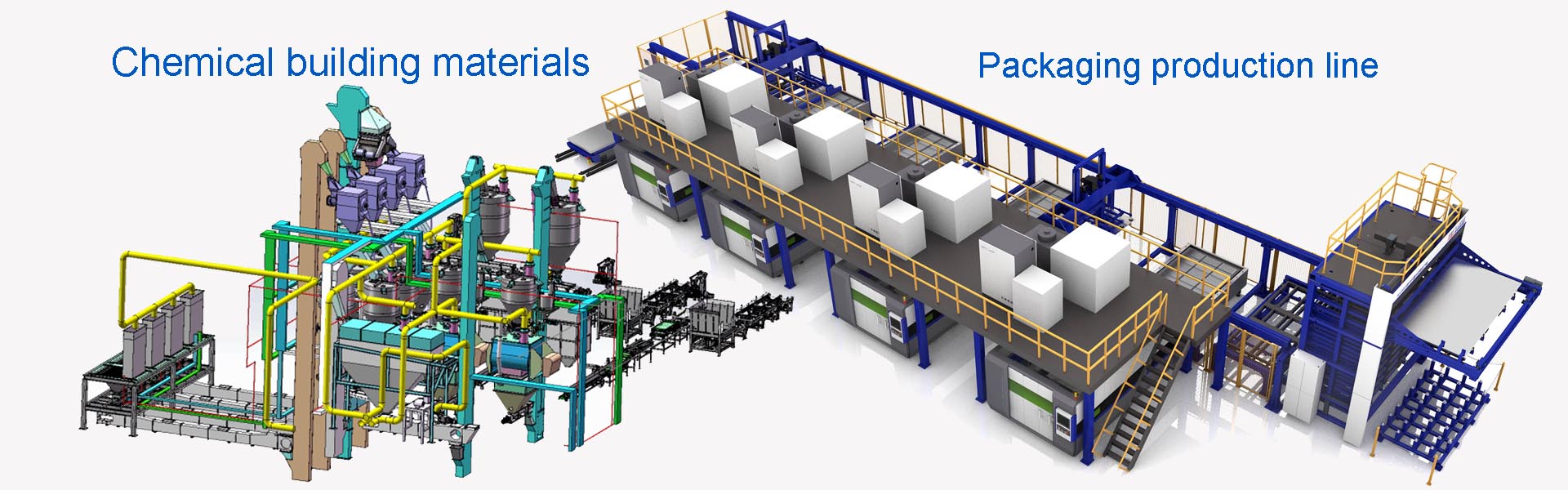

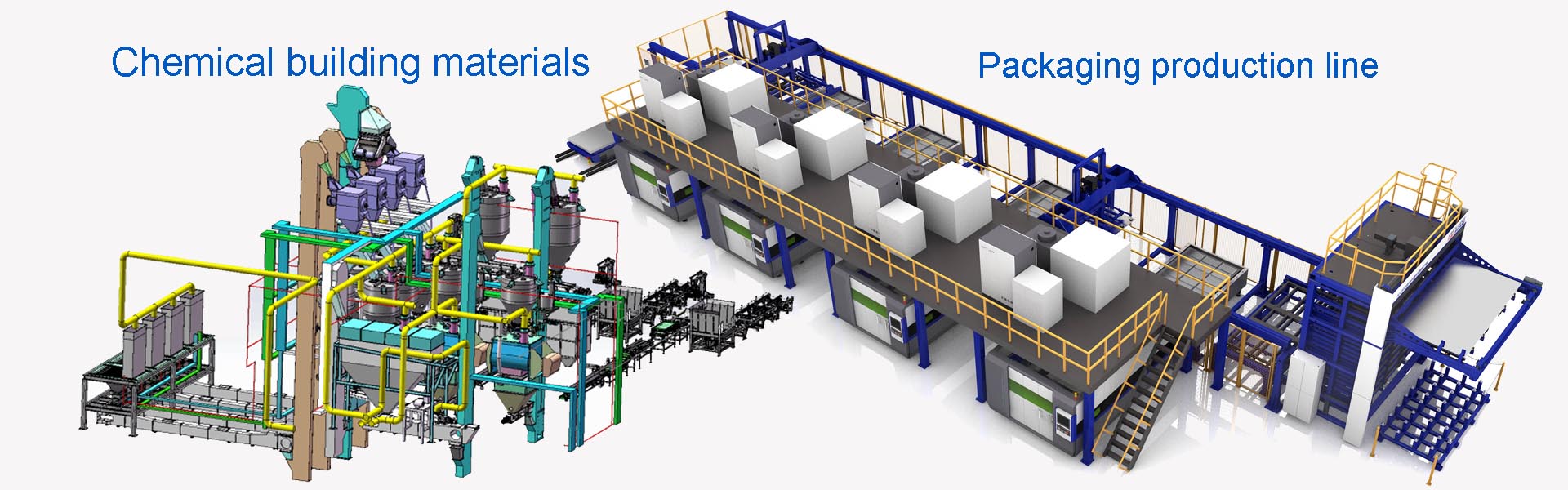

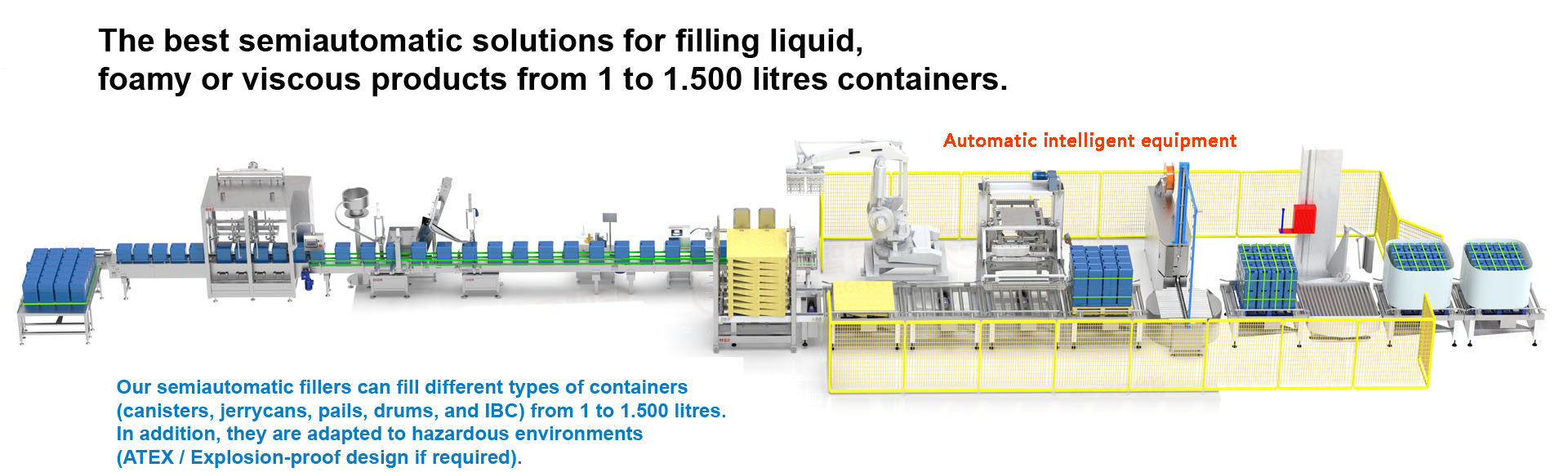

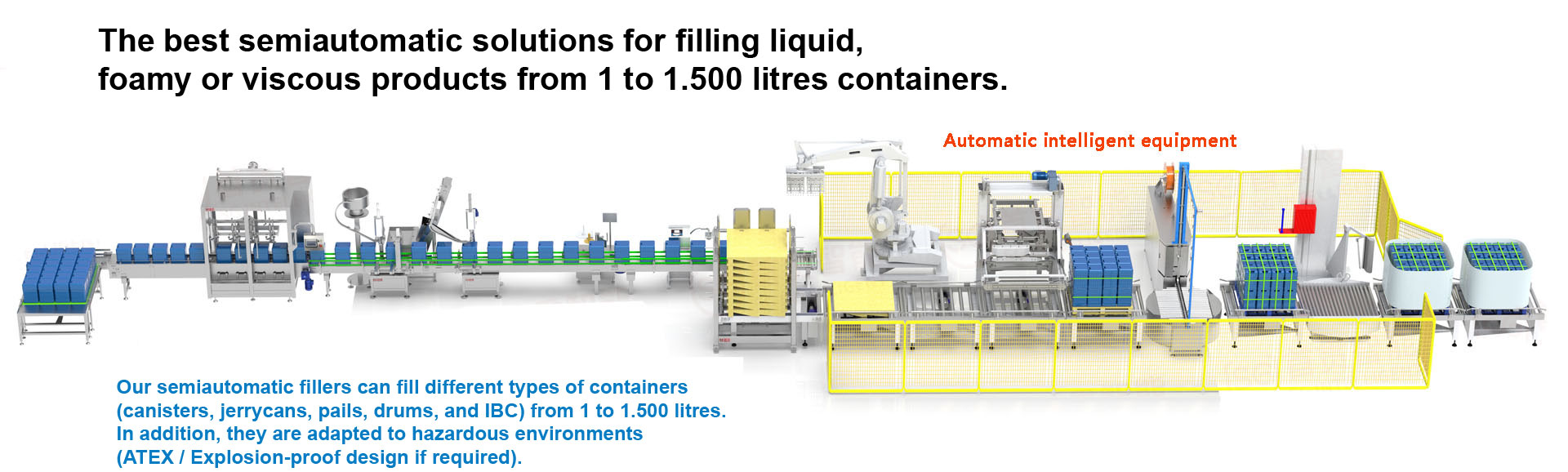

| Suitable material | Liquid like coating, printing ink, paint, asphalt, glue, lubricant, petrochemical, fineness chemical etc |

| Weighing form | Filling above level (liquid without foam) Filling under level (liquid with foam) |

| filling station | 2 |

| Filling capacity | 10-60KG |

| Accuracy | 0.2% |

| Filling speed | 300-420 barrels/hour |

| Barrel form | Pail, Can, Bottle, Tin, Drum, IBC, etc. |

| Gas power | 0.5MPa |

| Work environment | Temperature :-20oC~45oCrelative humidity:95%(none dew) |

| voltage | AC380/AC220V ± 10% 50Hz |

| Max power | 1KW |

| Filling mouth material | SUS304/SUS316/PTFE |

| Option | Explosive proof |

1.For the filling of square barrels and drums below 100kg, thesystem adopts programmable PLC control, with full Chinese quid.ance and easy operation;

2.The filling head extends into the barrel mouth and automaticaly exits when filling is completed. lf the filling head is not alignedwith the barrel mouth, it will automatically return;

3.The filling gun is made with integral technology to preventdripping and splashing; the quick-release connector is easy toisassemble ano cean;

4.The system target value can be set freely, and the height of thefilling gun is adjustable, suitable for rapid filling of packaging barrels of varlous specifications.

5.Equipped with a large and small ball width group and a dou-ble-stage filling gun, the four-stage filling design of large,medium, small and trace quantities makes filling more accurate,Filling is prohibited without a bucket on the weighing platformand differential pressure zero-time bucket collision protection isprovided:

6.Net weight/gross weight (automatic tare for each barrel) Twofilling methods are automatically selected;

7.One-click operation, easy to use; multiple windows display filling volume, number of barrels, cumulative volume and other in-formation;

8.There is a signal indicator light for real-time display, and an au.tomatic alarm if the deviation is exceeded;

9.It has good stability, reduces losses, saves costs, improves operating efficlency and reduces manual operation pressure.

Why choose us

we provide professional packaging and logistic service for your option. With plenty of experience and carefully treatment, we make sure the machinery delivery to you is good useful.

2. Pre-sale Service.

pre-sale service will provide by our sales engineers and electrical engineers. offering complete bundle of packaging solutions and professional rationalization proposals and pre-sale testes.

3. After-sale service

we provide free parts and parts delivery, when manufacture defects has been detected during normal operation(vulnerable parts not included)under warranty period(one-year warranty )as well as after-sale service of low cost.

Free training course will be given to your technician at our factory site in Shanghai China.

-

Semi-Automatic Weighing Filling Machine for Filling 180L Paint Ink/Solvent Coating[2025-07-04]

-

Liquid About 10L 15L 20L 25L 30L 50L Pail Chemical Explosion-Proof and Anti-Corrosion Filling Machine for Paint/Perfume/Glue/Glyphosate[2025-03-31]

-

Semi-Automatic Ex-Proof Slurry Swing Arm Type 4-200L Drum Filling Machine[2025-07-05]

-

Fully Automatic Line Double-Head Emulsion 200L HDPE Drum Filling Machine[2025-04-03]

-

Fill Fruit Juice Paste Concentrate in Box Drum Liquid Filling Machine[2025-04-14]

-

1000L IBC Tote Polyether Quantitative Filling Machine - Intelligent Automated Liquid Packaging System[2025-05-17]

-

30 L Semi-Automatic Quantitative filling machine Recommended filling valves[2025-06-30]

-

Explosion-Proof Type filling machine What is the development trend[2025-07-01]

-

Automatic 200L Steel Drum Filling Machine for Lube Oil[2025-06-07]

-

200L Plastic Bottle Bottle Carbonated Beverage Filling Machine[2025-06-12]

-

Small Semi-Auto Bottle Honey Juice Chili Sauce Filling Semi Auto Ink[2025-04-12]

-

Automatic Anti Corrosive Strong Acid Liquid Chlorine Bottle Filling[2025-04-12]