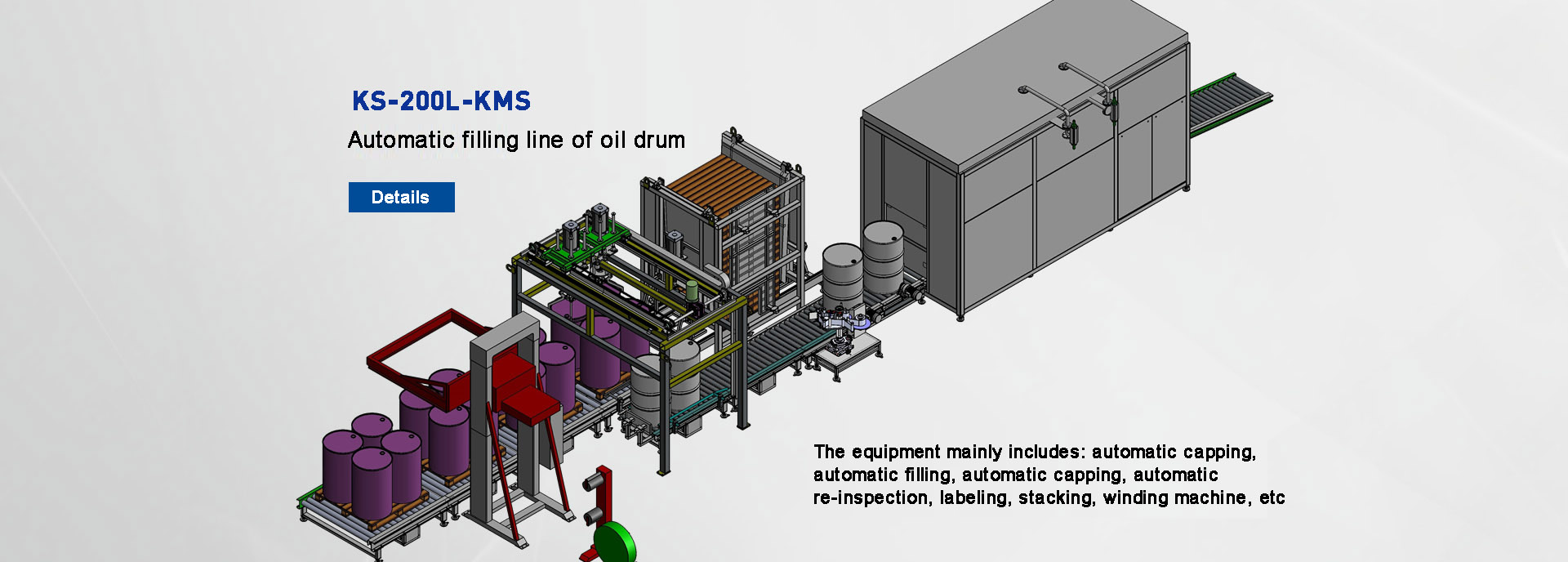

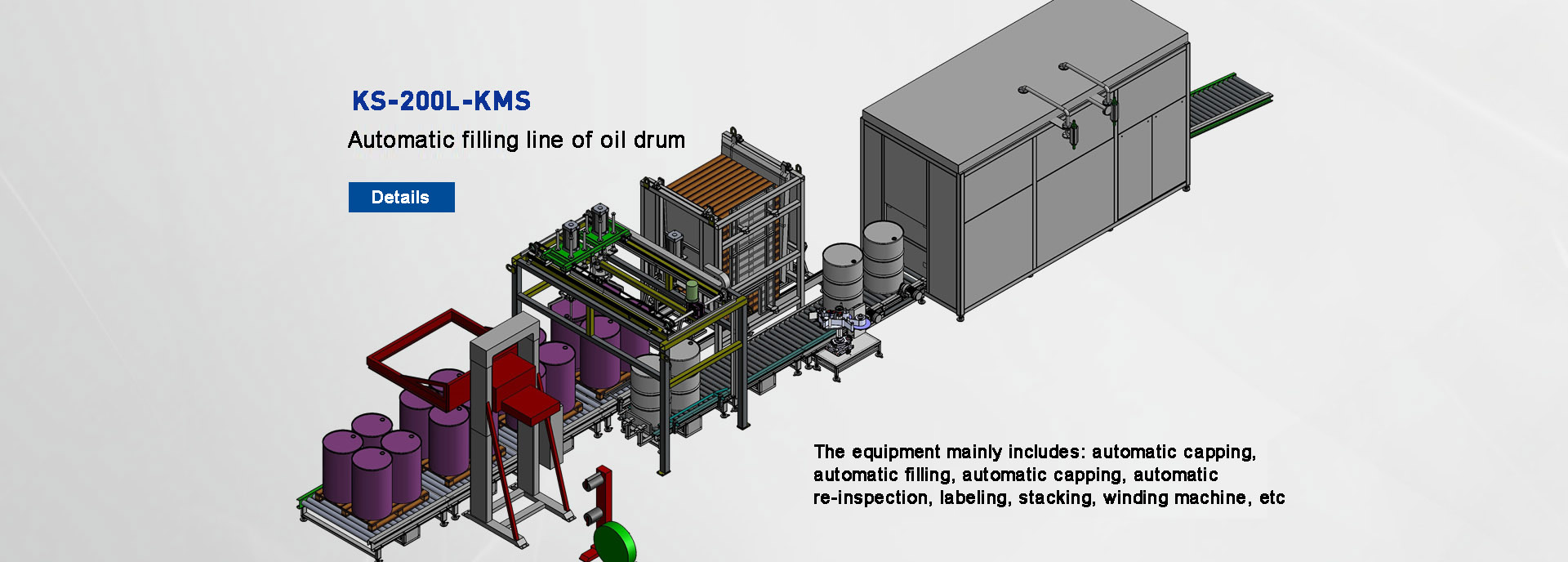

Corrosion-Resistant Barrel Type Quantitative Fully Automatic Vat Glacial

2025-04-12 15:51:40

glzon

How to operate

During operation, as long as the empty barrel is installed on the empty barrel pipeline line, it will automatically stop and the

The nozzle device automatically places the empty barrel directly below the nozzle of the nozzle; the nozzle valve automatically lowers into the

After entering the barrel mouth, the empty barrel is automatically tared, and then the specific gravity is determined accurately at two speeds.

bundle, the spray valve automatically connects to the outside of the barrel, enters the full barrel pipeline, and reaches the capping position.

The piping machine stops, the cap is placed manually, the capping machine is pulled down to cap, and the weight is completed.

During operation, as long as the empty barrel is installed on the empty barrel pipeline line, it will automatically stop and the

The nozzle device automatically places the empty barrel directly below the nozzle of the nozzle; the nozzle valve automatically lowers into the

After entering the barrel mouth, the empty barrel is automatically tared, and then the specific gravity is determined accurately at two speeds.

bundle, the spray valve automatically connects to the outside of the barrel, enters the full barrel pipeline, and reaches the capping position.

The piping machine stops, the cap is placed manually, the capping machine is pulled down to cap, and the weight is completed.

Features

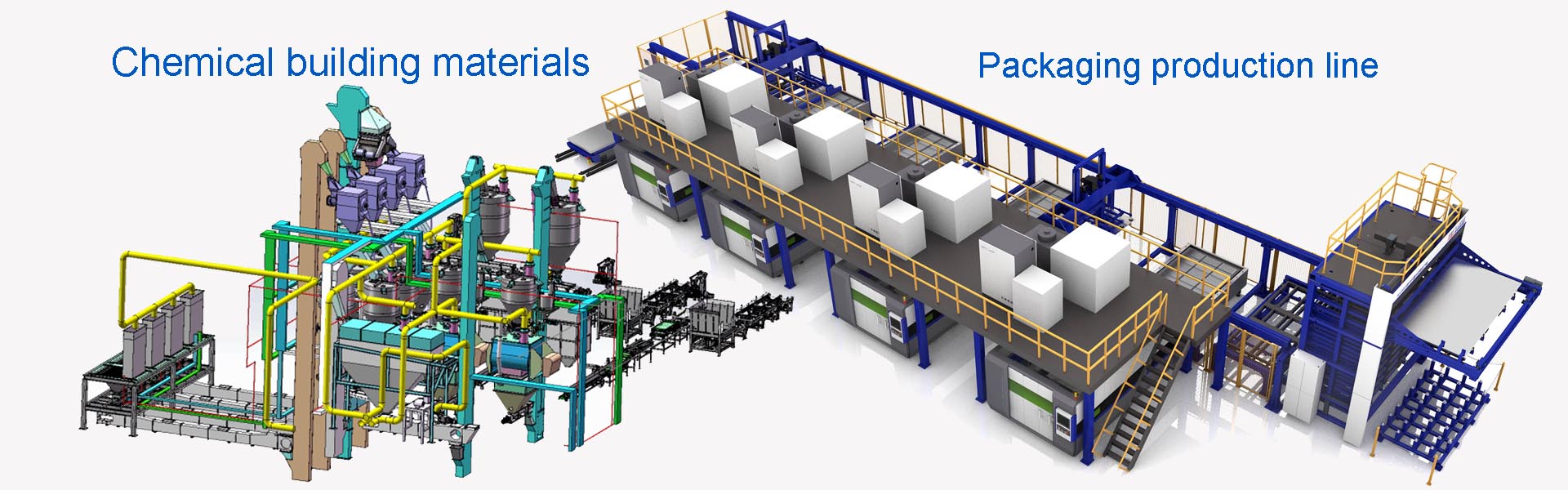

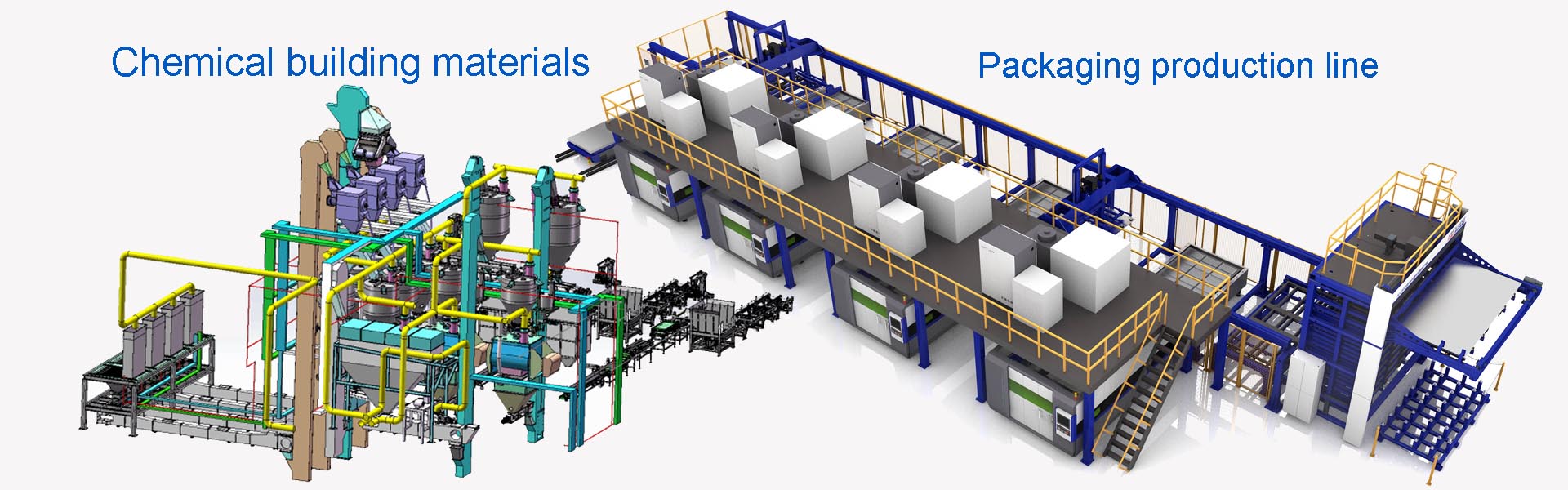

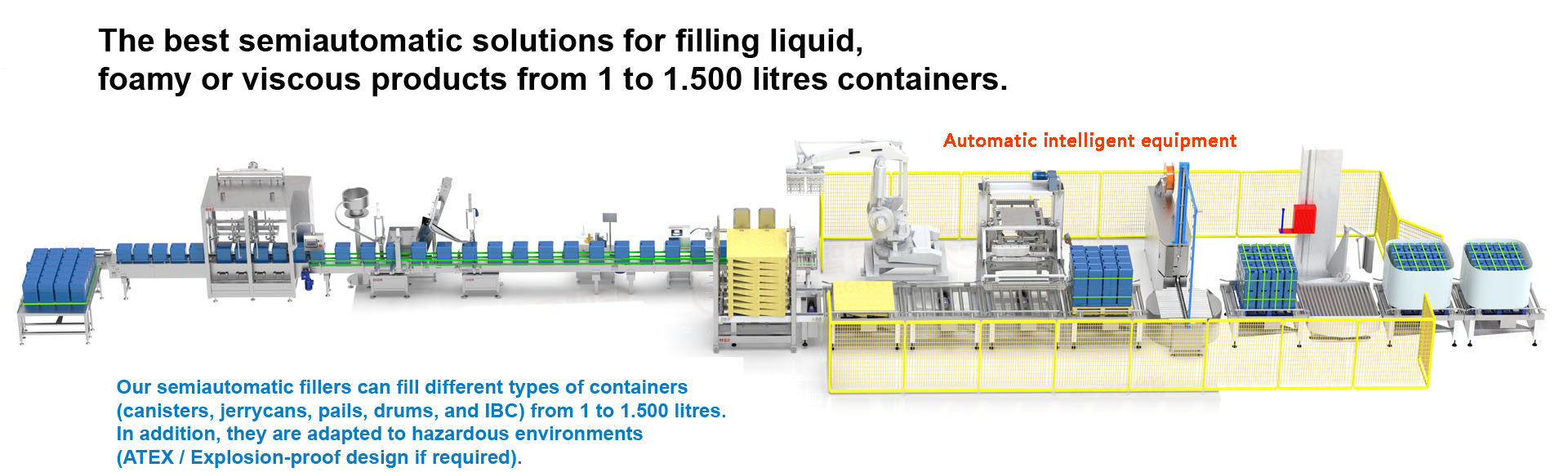

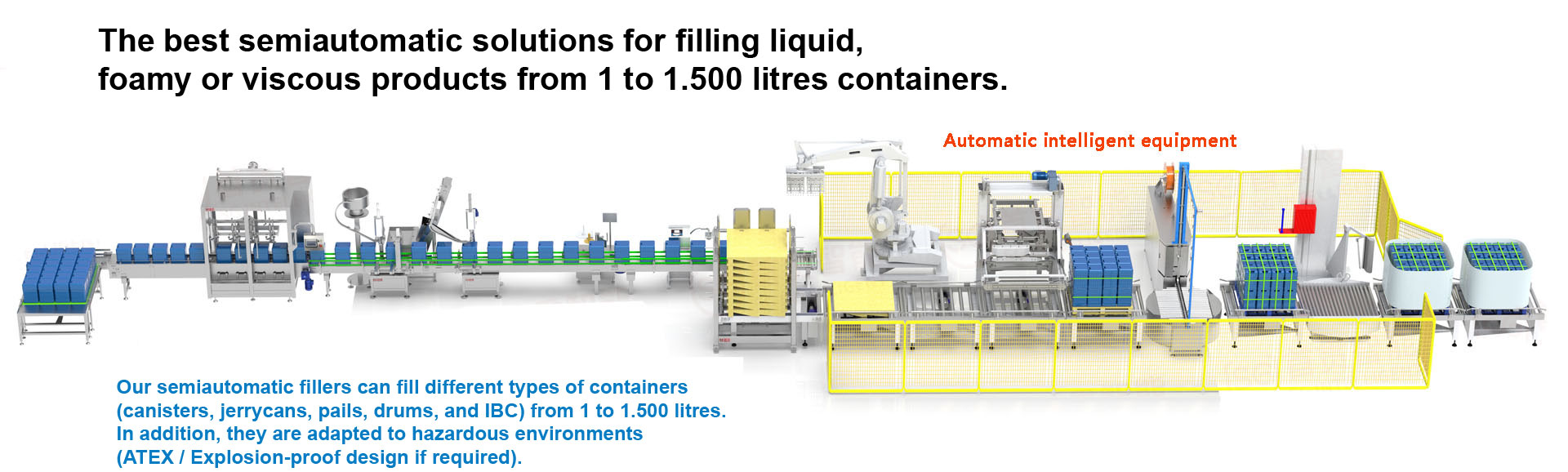

The automatic canisters filling machine is one of our advanced filling solutions for liquid or viscous products. It is indicated for the filling of 1 to 30 liters round or rectangular based metallic or plastic canisters, pails and jerrycans. It also may be equipped with multiple workstations.

This model is designed for high filling productions featuring a high level of automation. With the automatic canisters filling machine, we guarantee maximum automation coupled with total packaging flexibility in one system.

Complete automation: our filling machines reduce the need for manual labor and minimize the risk of human errors. This allows you to optimize your resources and increase production capacity.

-

Small Semi-Auto Bottle Honey Juice Chili Sauce Filling Semi Auto Ink[2025-05-06]

-

Semi Auto Powder Filler / Dry Powder Filling Machine[2025-04-12]

-

Fresh Orange Juice Production Line Juice Washing Filling Roll Film Filling Machine[2025-05-06]

-

Efficient 200L Phosphoric Acid Coupling Agent for Factories[2025-07-04]

-

Semi-Automatic Liquid Cream Paint Cans Piston Filling Machine for 30L[2025-05-09]

-

5kg 25kg Bags Filling Rice Packing Machine[2025-04-21]

-

Freeze-Dried Powder packaging machine[2025-07-31]

-

Full Automatic Honey Processing Machine and Filling Machine[2025-04-11]

-

200L Fully Automatic High Temperature Bitumen/Asphalt Filling Machine[2025-04-15]

-

Industrial Paint Filling Machines for Wall Paint - Latex - Coatings[2025-07-16]

-

Semi Automatic Drum Filling Machine for Engine Oil & Lubricant Oil Reliable Drum & Tote Filling System[2025-05-30]