Bucket Paint Filling Machine Semi Automatic and Automatic Paint Filling Systems 2

Heavy-Duty Ton Barrel Filling System: Efficiency, Safety, and Precision

Overview

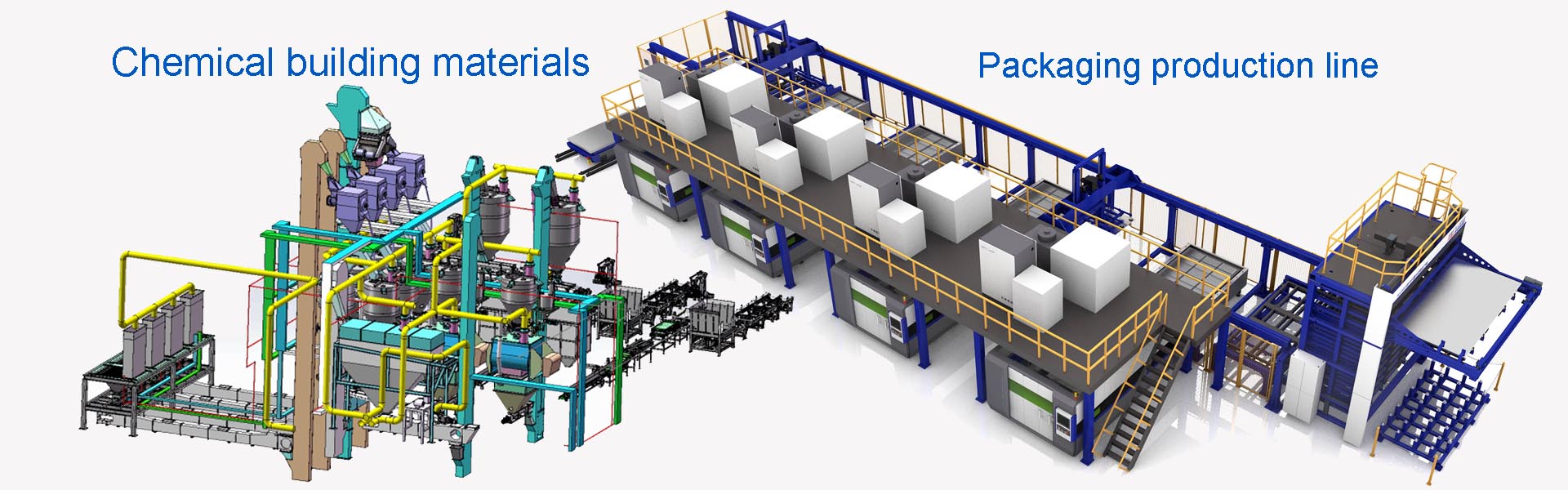

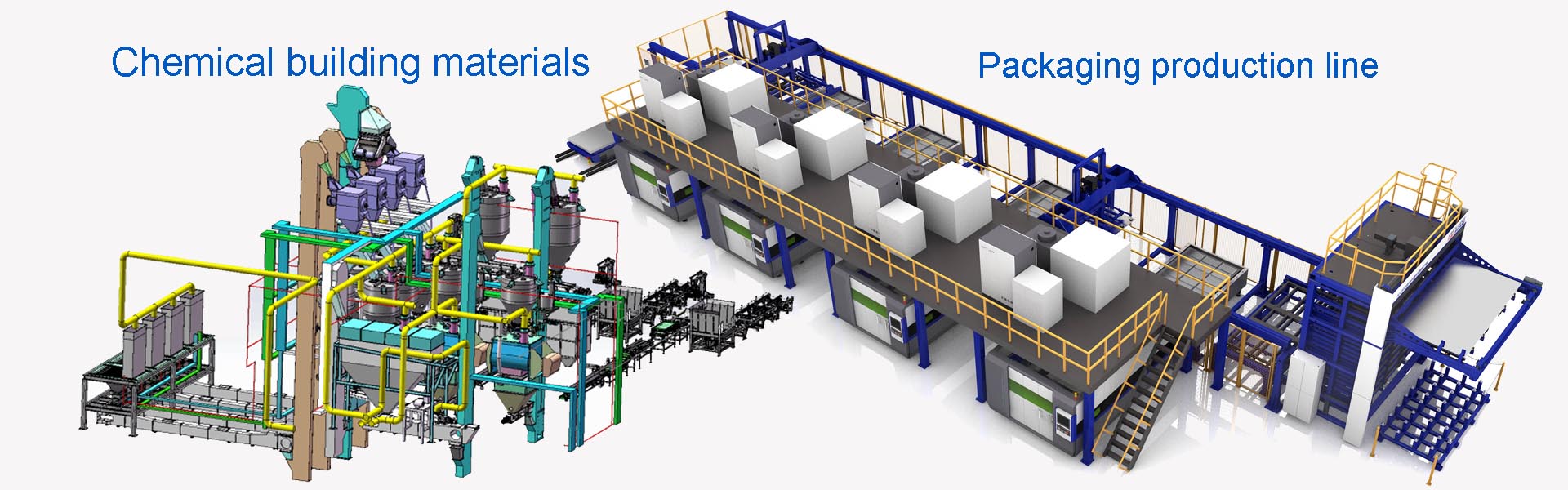

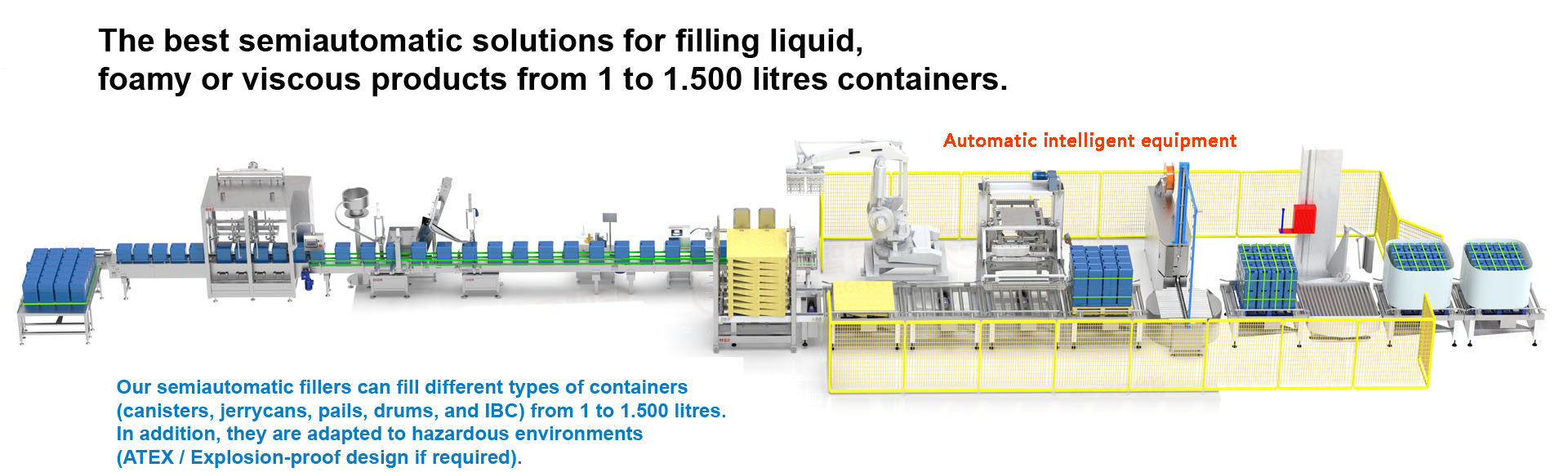

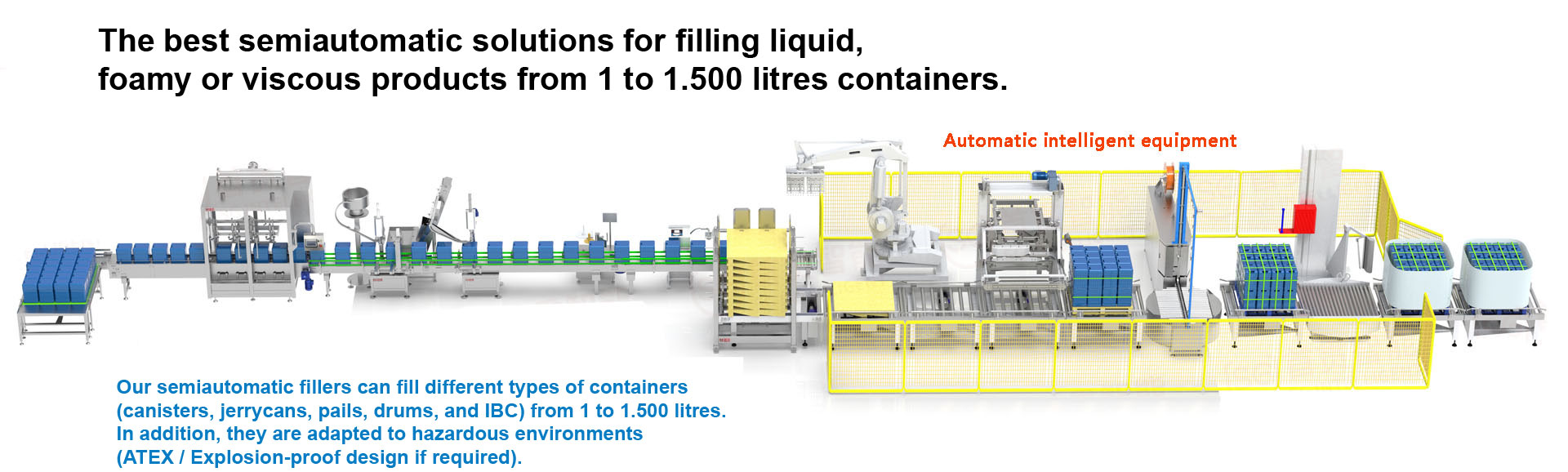

The Heavy-Duty Ton Barrel Filling System is designed for high-capacity, efficient filling of industrial liquids into IBC totes (1,000L), drums, or ton barrels. Ideal for bulk chemicals, oils, paints, adhesives, and food-grade products, these systems ensure precision, safety, and compliance with hazardous material handling standards. Both semi-automatic and fully automatic configurations are available to match production scale and workflow requirements.

System Options

1. Semi-Automatic Ton Barrel Filling Machine

Operation: Manual positioning of barrels; automated filling with operator oversight.

Key Features:

High-Flow Filtration: Fast filling rates (up to 200 L/min) with minimal splash.

Adjustable Nozzles: Customizable fill heights to prevent foaming or spillage.

Viscosity Handling: Suitable for thin to thick liquids (e.g., oils, resins, coatings).

Safety: Grounded equipment, spill containment, and ATEX/IECEx options for flammable environments.

Weighing Scales: Optional integrated load cells for precise net weight filling.

Ideal For: Small to medium-scale operations, batch processing, or multi-product facilities.

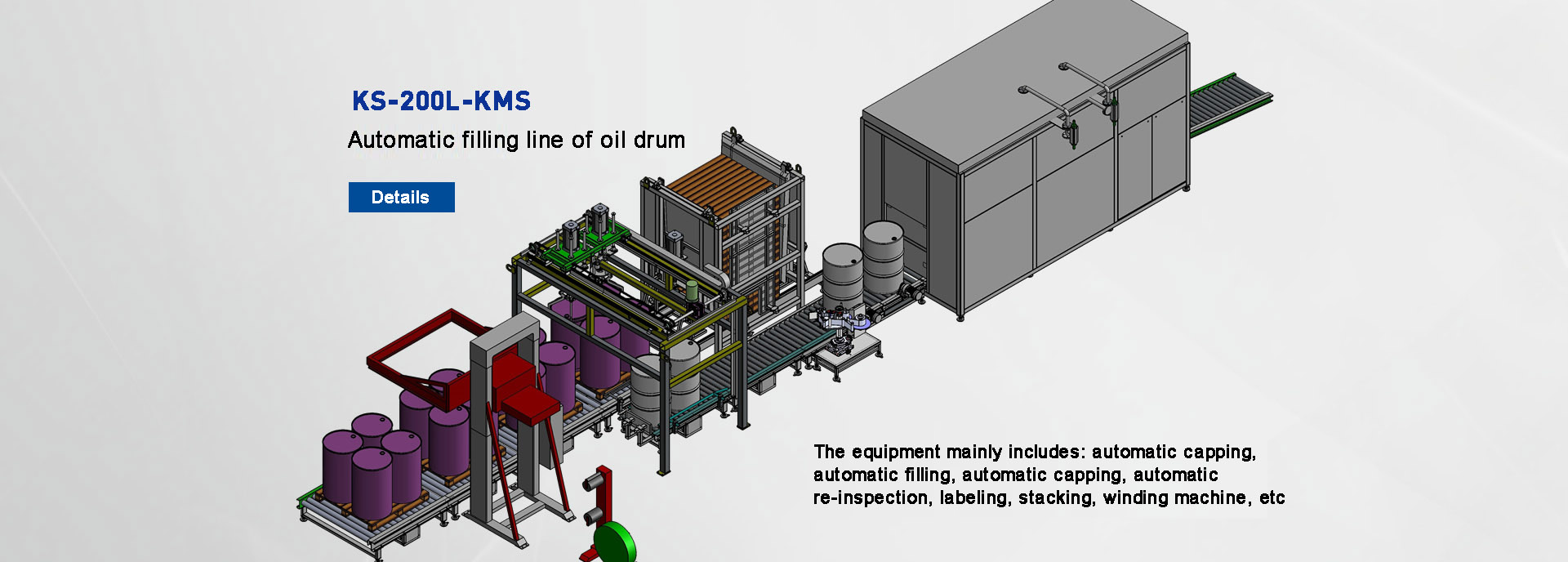

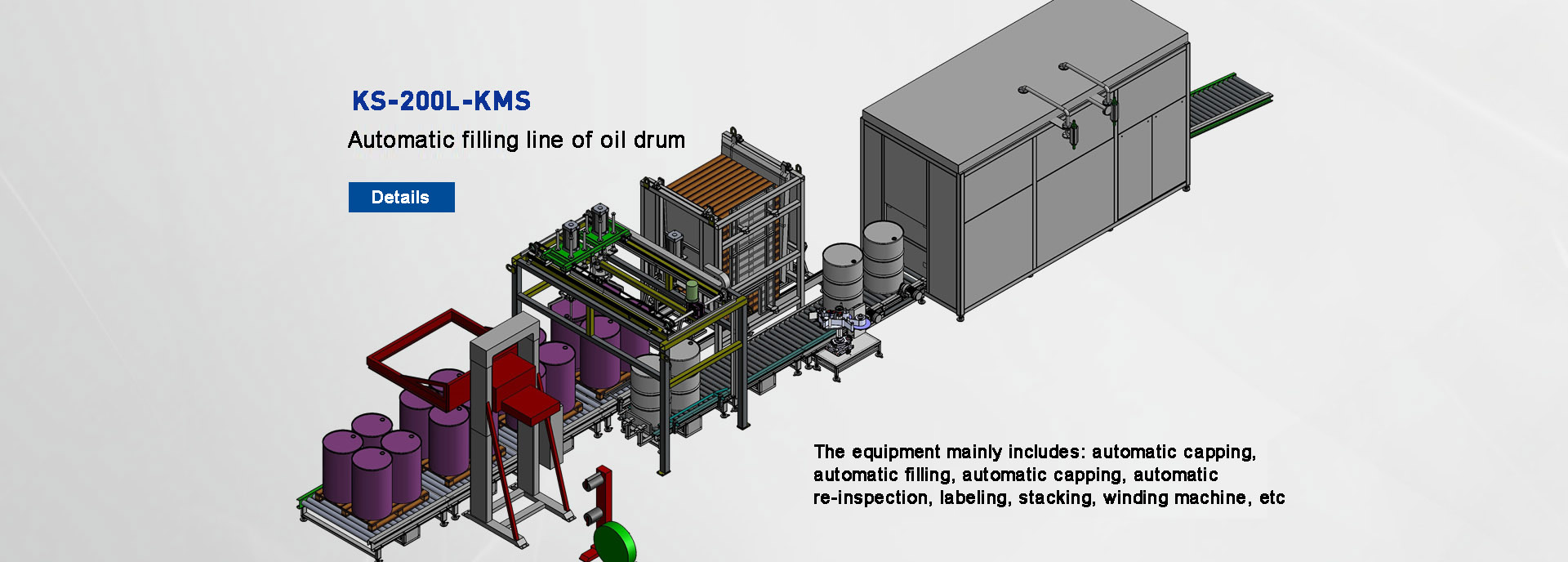

2. Fully Automatic Ton Barrel Filling System

Operation: Automated conveyor, indexing, filling, and capping/sealing.

Key Features:

Throughput: Up to 15+ barrels per hour (depends on viscosity and product).

Touchscreen HMI: Programmable for multiple barrel types, sizes, and fill volumes.

Automated Lidding: Press-on lids, crimping, or sealing for secure closure.

Nitrogen Blanketing: Prevents foaming, oxidation, or contamination during fill.

Weight-Based Filling: High-precision load cells for ±0.1% accuracy.

Cleaning: CIP (Clean-in-Place) or quick-disconnect nozzles for easy maintenance.

Remote Monitoring: IoT-enabled systems track fill data, alarms, and performance metrics.

Ideal For: Large-scale production, high-volume manufacturers, and industrial facilities.

Key Benefits

Efficiency: Reduces labor costs and cycle times with automated processes.

Precision: Accurate fill levels (±0.1%) minimize product waste and rework.

Safety: Drip trays, fume extraction, and ATEX/IECEx certifications for hazardous areas.

Versatility: Compatible with IBC totes, drums, and custom ton barrels (plastic, metal, or stainless steel).

Customization: Options for nitrogen blanketing, heated hoppers, and RFID tracking.

Compliance: Meets OSHA, ISO, and industry standards for chemical and bulk liquid handling.

Applications

Chemicals: Industrial solvents, acids, bases, and specialty chemicals.

Oils & Lubricants: Engine oils, greases, transformer oils, and biofuels.

Food & Beverage: Edible oils, syrups, sauces, and bulk liquid ingredients.

Pharmaceuticals: APIs, bulk intermediates, and liquid medications.

Paints & Coatings: Water-based, solvent-based, and high-viscosity coatings.

Optional Features

Vacuum Filtration: Removes air bubbles or contaminants before filling.

Riser Rings: Minimizes splash and foaming during filling.

Barcode/RFID Tracking: Logs batch numbers, expiration dates, and traceability data.

Multi-Head Filling: Parallel nozzles for higher throughput (up to 4x speed increase).

Chemical-Resistant Materials: Stainless steel (304/316L), Hastelloy, or PTFE coatings.

Automatic Palletizing: Seamless integration with robotic or manual palletizing systems.

Clean-in-Place (CIP): Automated cleaning cycles for hygiene-critical applications.

Level Sensors: Ultrasonic or radar sensors for precise fill level control.

How It Works

Barrel Placement: Manual (semi-auto) or automatic (conveyor) positioning of barrels.

Filling Process:

The nozzle descends into the barrel.

A high-flow pump or mass flowmeter dispenses the precise volume of liquid.

Nitrogen blanketing (optional) prevents foaming or contamination.

The nozzle retracts, and excess product is reclaimed (optional).

Sealing: Optional automated capping or lid pressing.

Discharge: Filled barrels move to downstream processes (e.g., labeling, palletizing).

Why Choose This System?

Reliability: Robust design with minimal maintenance requirements.

Scalability: Easily expandable for future production needs.

Expert Support: Custom engineering, installation, and lifetime technical support.

Contact Us for a customized solution tailored to your specific ton barrel filling needs!

Immediate Order:

Website: http://www.azoki.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Fully Automatic Mouth-Finding Coating Cans Filling Machine for 5-25L[2025-05-14]

-

Automatic Mouth-Finding Filling Machine Is Suitable for Ink Solvent/Polyurethane Filling[2025-04-30]

-

Industrial-Grade Bulk Filling Equipment for 1000L Containers[2025-05-28]

-

Semi-automatic Filling Machine for Chemicals, Oil & Lubricants | Barrel, IBC & Tote Filling System | Feige-Compatible[2025-05-29]