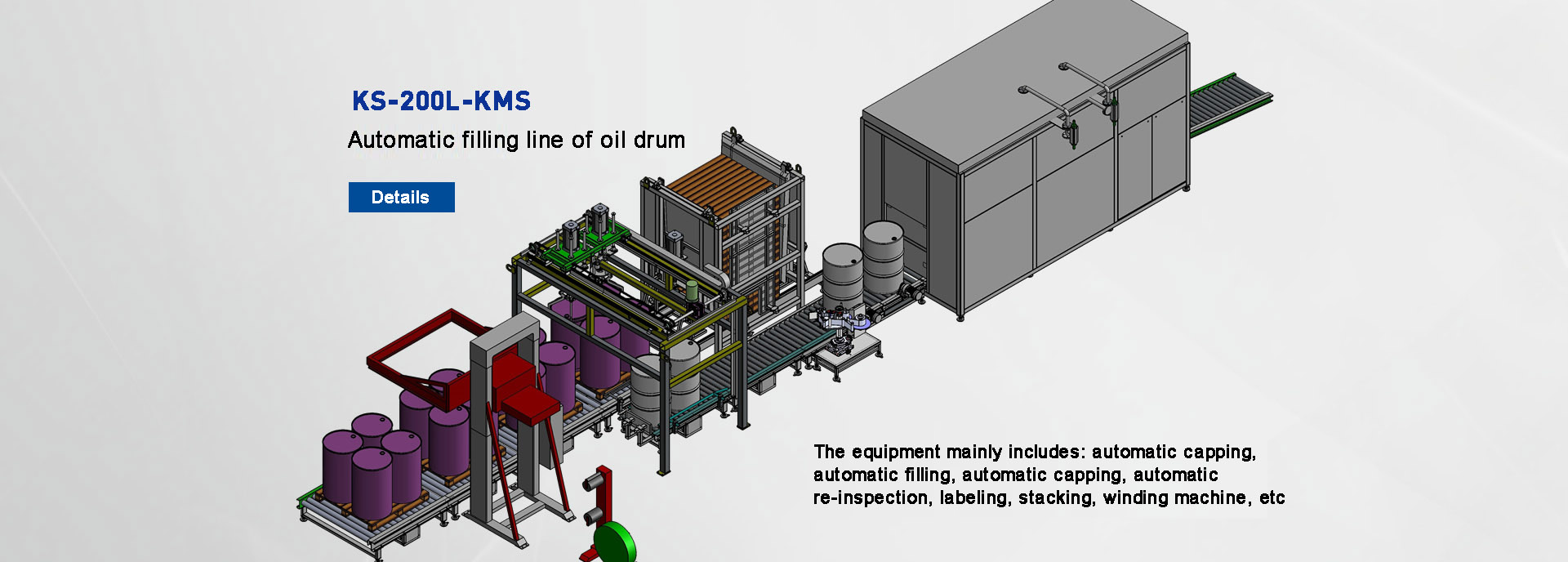

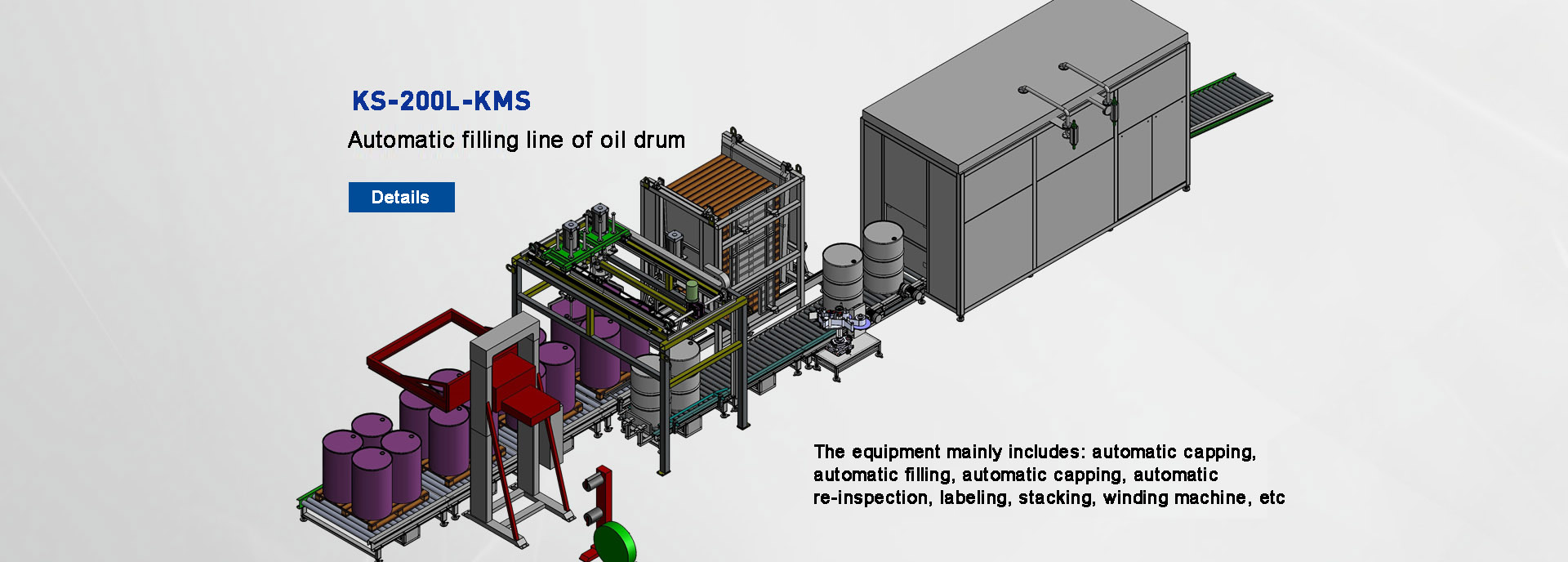

Fully Automatic Line Ex-Proof Epoxy Resin on Liquid Surface 200L Drum Filler

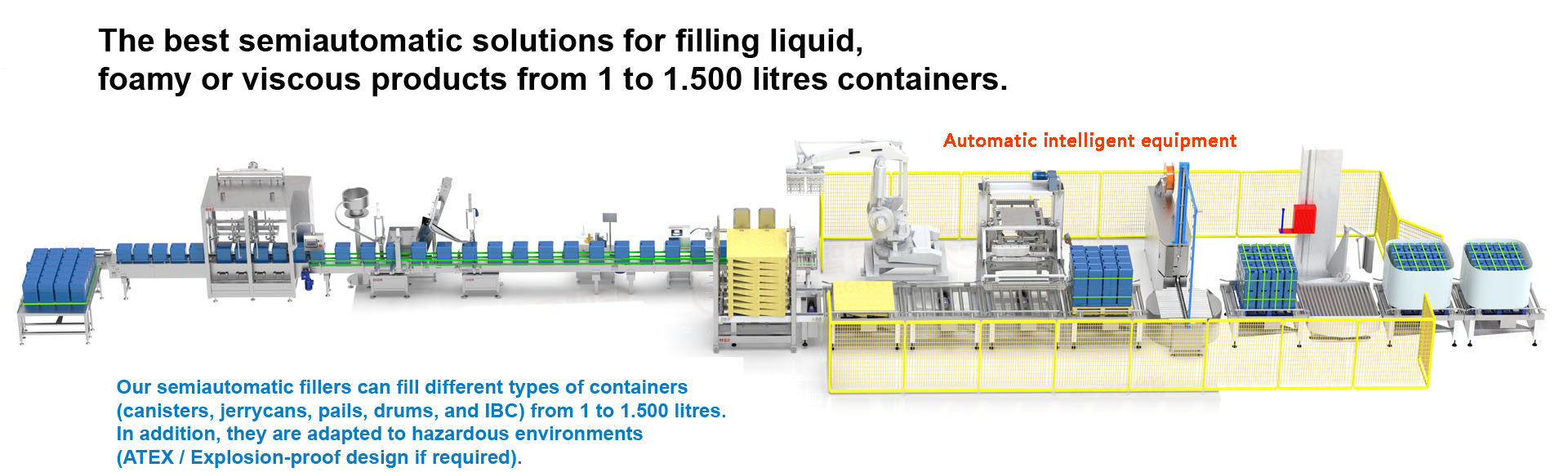

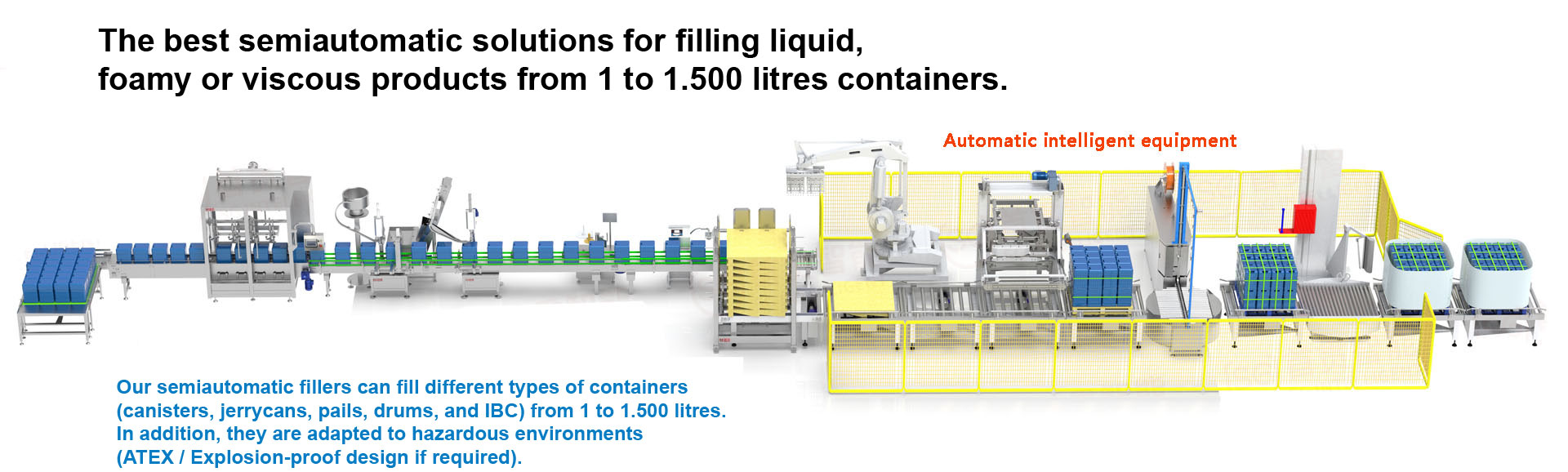

Suitable for 200kg barrel filling, the system adopts programmable PLC control, English-guided operation, and easy operation;

Automatic capping, automatic full barrel conveying.

Use automated material handling equipment to handle outbound and inbound shipments.

Automatically control the feeding pump, no filling without a barrel.

The weighing value is displayed in real time.

Feeding speed is fast or slow.

Net weight/gross weight two filling methods.

Automatic/manual operating mode.

Emergency stop/power outage/can removal triple protection.

Explosion-proof control box explosion-proof mark, EXIDIIBT6.

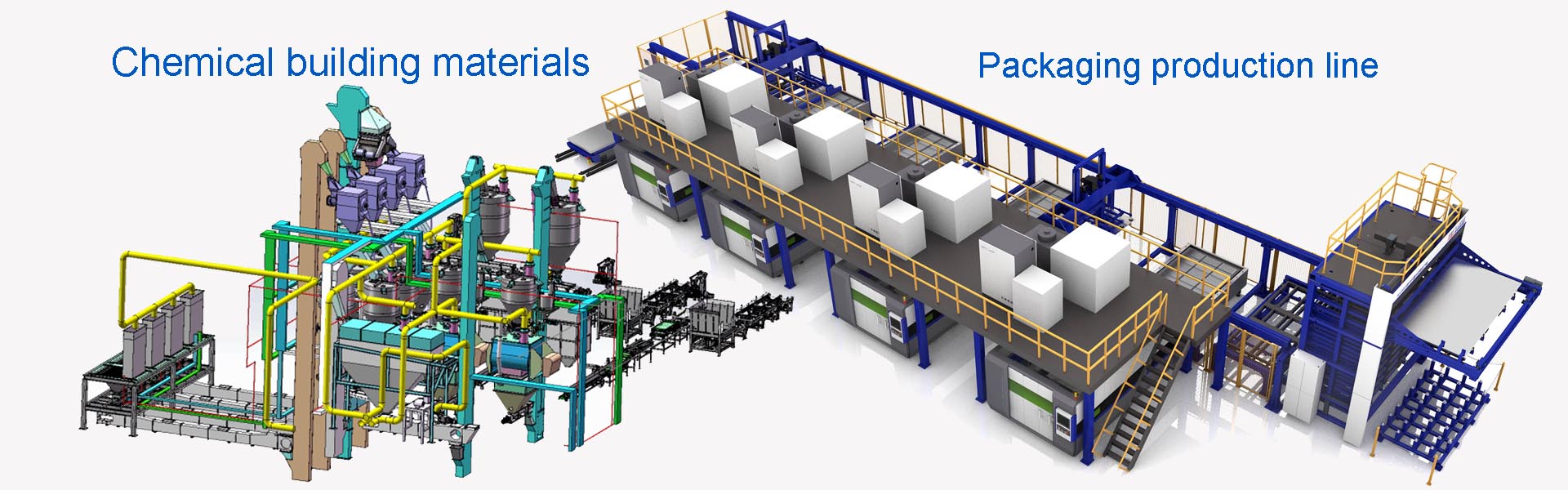

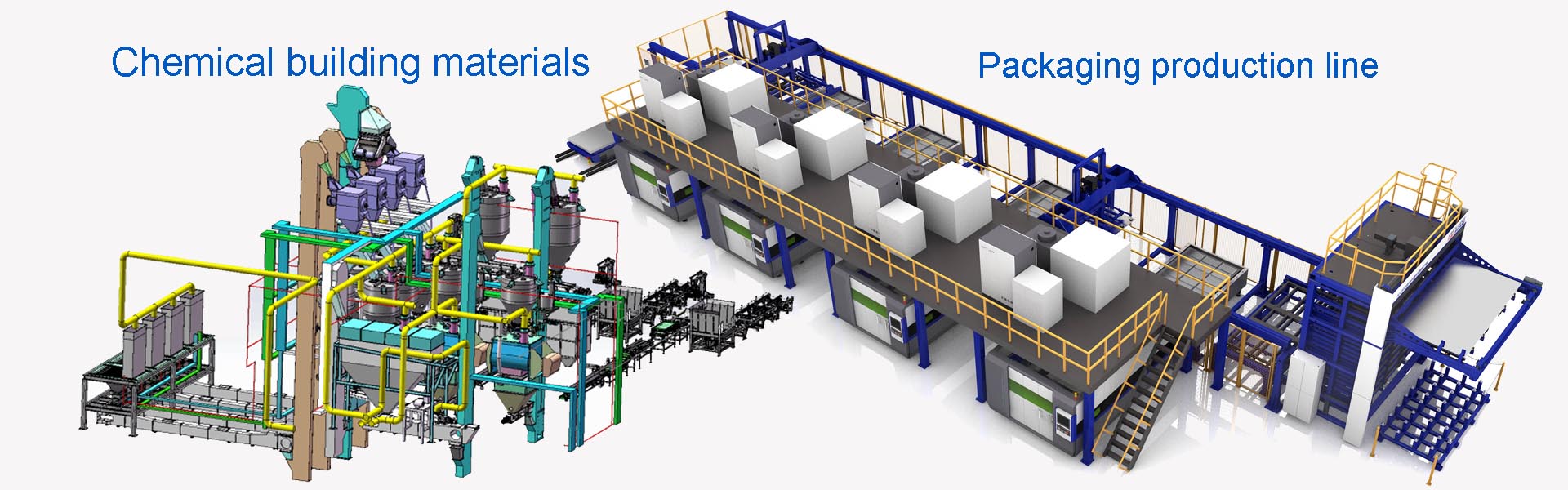

Three-dimensional warehouse, high-rise shelf warehouse, automatic storage and retrieval system AS/RS (Automatic Storage & Retrieval System). It generally uses several, dozens or even dozens of layers of shelves, and uses automated material handling equipment for warehouse entry and exit operations. Three-dimensional warehouses generally consist of high-rise shelves, material handling equipment, control and management equipment, as well as civil engineering and public facilities. The automated three-dimensional warehouse is the crystallization of high technology in the modern logistics industry. It integrates machinery, electrical, software, communications and information. It requires the collaboration of multiple disciplines to complete. With its strong technical strength and product development capabilities, Shunli has accumulated twelve years of experience in design, production, and installation. The factory has intelligent management and advanced automated production and manufacturing equipment to provide guarantee for the production and manufacturing of high-precision logistics and warehousing equipment. The company independently develops high-performance forklifts with a maximum traveling speed of 400 meters/minute, reaching the leading level in Asia. And cooperate with world-class drive and electrical control (SEW, DEMAG, SIEMENS, LEUZE, SICK, OMRON) brandsReach long-term cooperation and strive to provide customers with the most stable systems and equipment.

-

Shared packaging machine _Latex Powder packaging machine [2025-07-26]

-

Automatic Gland Weighing Filling Machine for 50-30L Glacial Acetic Acid Filling[2025-04-07]

-

Glycerin filling machine _Small Typefilling machine[2025-07-18]

-

Weighing packaging machine _-Reliable technology [2025-07-24]

-

Heavy-Duty Explosion-Proof 10L Hopper for Juice and Yogurt Production[2025-05-30]

-

Ton Bag Weighing packaging machine _How to adjust packaging speed [2025-07-24]

-

Real Stone Paint Explosion-proof Filling Machine with a Crown Lid, Easy to Operate with Touch Screen[2025-05-05]

-

Explosion-proof Filling Machine for High Precision[2025-04-29]

-

Automatic Liquid Filling Machine Anti-Corrosion Detergents Filling Machine[2025-04-24]

-

No-Spill Automatic Quad Drum Filler Reliable Liquid Packaging Solution[2025-06-04]

-

Thinners filling machine Automation filling machine[2025-07-16]

-

Liquid Filling Machine with Servo Motors[2025-06-07]